Please check order confirmation emails to ensure shipping addresses are complete

Decal Application

- I recommend the surface to receive the decal be clean and have a gloss finish. I like to have the following available for the session: clear work area, reference pictures for where the decals should be located go on the model, sharp scissors appropriate for cutting small areas of paper, a sharp hobby knife, tweezers, a bowl or cup of warm water, a plastic tray or plate containing a moistened paper towel or sponge, cotton swabs or tissues for blotting, a holding area for models to receive decals, and a space for models that have just had decals applied. I also like to use setting solutions and decal solvents.

- Cut around the decals that are going to be applied in the session. I recommend working with a few to several. I don't like to cut around one decal, apply it, and then go back to cut out another decal. I like to cut out all of the decals that will go on one side of a model or one side of a couple of models. That way I can set up a little application routine. My Miscellaneous Miniatures decals are printed on one sheet of decal film. If the sheet is soaked in water, the entire sheet will lift from the paper. The graphics are not individual decals. I prefer using sharp scissors to cut around the decals. Sometimes I need to use the hobby knife but only if I can't use the scissors.

- I like to place several individual decals on a moistened paper towel so that they decal film will slide from the backing paper. If the paper towel is fairly moist, the small decals normally don't take too long to soak through and become ready for application. Sometimes I do need to let them float in a bit of water for a short time. I try to avoid the floating bit though as the decals will normally lift from the paper or lift and sink which leads to a decal fishing operations.

- While the decals are resting on the moist towel, apply some setting solution to the area that will receive the decal. When the decal is ready, carefully move it from the towel and slide/place it where it's needed. Use a toothpick, paint brush, or other appropriate tool to finalize the position of the decal on the model. Then, carefully blot the decal to remove air bubbles and excess water. Once this is done, double check that the decal didn't move. If it did, apply some more setting solution and carefully move the decal back into place.

- Carefully apply the remaining decals while avoiding the decals that are in place. As mentioned earlier, I prefer to work on one side of a model or group of models, the work on the other side. I also like to work from the center out, starting on the fuselage and tail working my way to the wings. Doing this I find that I'm less likely to accidentally hold or touch recently applied decals.

- Once the decals are in place I'll apply decal solvent to help the decals conform to model details such as panel lines, rivets, or contours. If air was trapped under the decal I will carefully poke a hole in the decal with a sharp instrument, apply some decal solvent, and try to press the air from the under the decal.

- Once the decals are the way I want them or are as good as they're going to get, I'll make sure they are dry and then coat them with a clear acrylic varnish. Once that's dry I'll coat the model with its final clear coat.

Tip for applying small decals

Tip and picture provided by Martin Gilling

Step 1 - Put a dab of water on the model where the decal will go

Step 2 - Lay the dry decal still on backing paper into the water on the model

Step 3 - Add a touch more water over the decal with a brush

Step 4 - After a few seconds the decal will release and can easily be slid/pushed into place

Customers have questions, you have answers. Display the most frequently asked questions, so everybody benefits.

Tutorial #1 Warped Resin

Before

In Progress

In Progress

Sometimes I find that my resin models have warped a bit during shipment or storage. Before I get too far into the project I'll reshape the model so that it looks the way it should.

Above is a 1/200 scale, resin He-177. It's a bit warped. Not to worry, it can be fixed without too much trouble.

In Progress

In Progress

In Progress

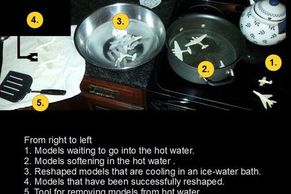

The process I use to reshape the warped models is to place them in hot water until the resin becomes soft and either falls back into shape by itself or if need be, can be easily nudged back into shape. Once the heated model is reshaped, I cool it rapidly by placing it in cold water. Once the model has cooled I set it aside until I'm ready to continue working on it.

The picture above shows several models in various stages of being reshaped. I've heated the water to near boiling and keep additional boiling water nearby, in the teapot in the picture below.

I place a couple of models in the hot water and let them rest there for a minute or so. Once I think they've had time to heat and soften I'll scoop them out with a fork or spatula.

I'll take a look at the model to see if it has returned to its original shape during the heating process. If it hasn't, I'll either heat it some more, or if the resin is soft, I'll carefully place the misshapen parts back into shape.

Once I'm satisfied with the look of the model I'll place it in ice water to cool and stiffen. After the model has been in the ice water for a couple of minutes I'll retrieve it and make sure it still looks correct. If it looks good I'll set it aside to dry, if not, I'll put it back in line to be re-softened.

After

In Progress

After

And here's that He-177 after having been in the hot tub.